Detail

|

Model |

SHGY33-3 |

SHGY33-4 |

|||

|

Performance |

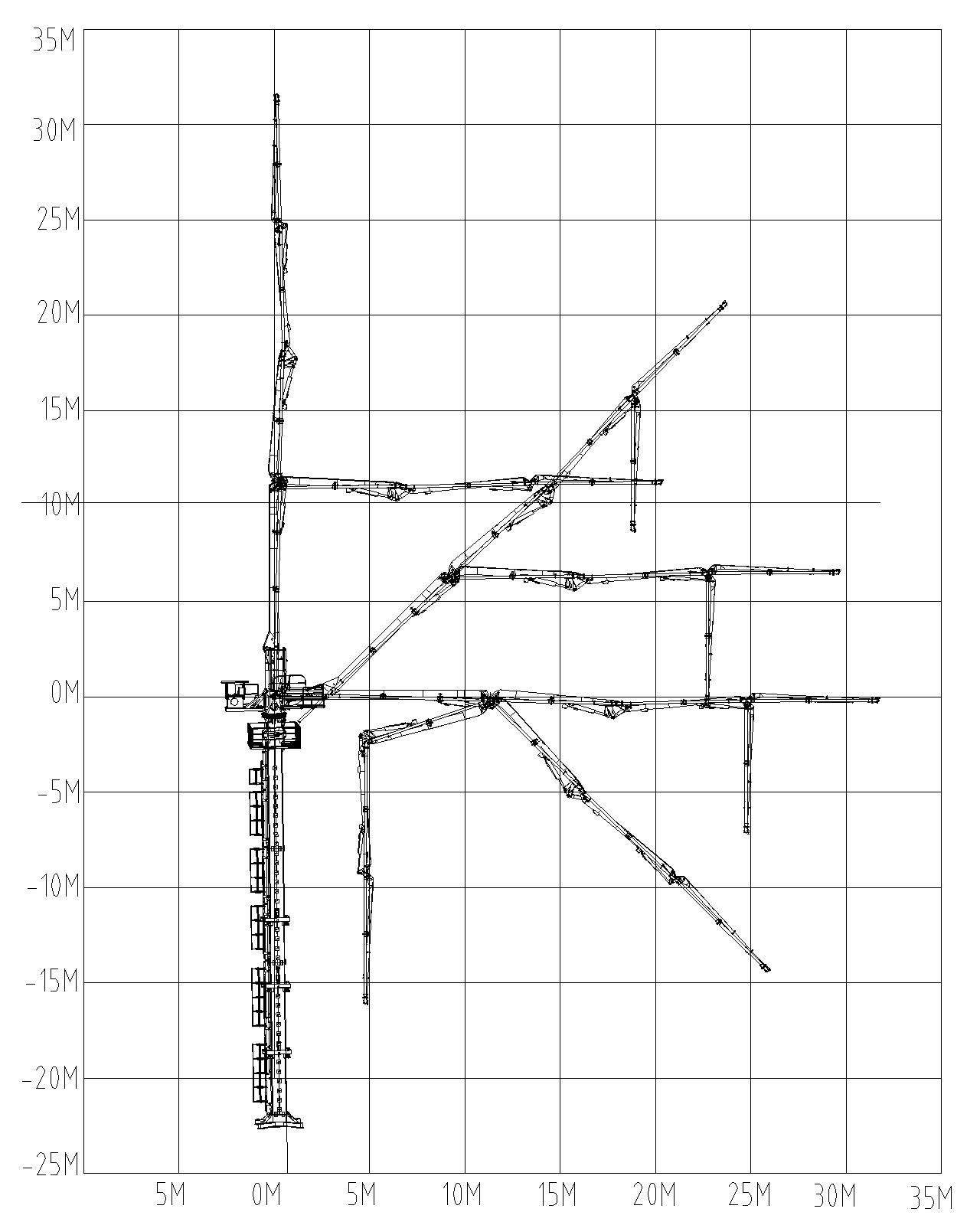

Max. Radius of Placing Boom(m) |

33 |

33 |

||

|

Free Standing Height ( to the joint between the end |

22.7 |

22.7 |

|||

|

slewing range( º ) |

400 |

360 |

|||

|

working temperature(℃) |

0〜60 |

0〜60 |

|||

|

Total Weight(kg) |

21000 |

21800 |

|||

|

Counter Weight(kg) |

NON |

NON |

|||

|

Power (subject to customers requirement) |

customerized |

customerized |

|||

|

Motor |

Model No. |

Y2 -160L-4 |

Y2 -200L-4 |

||

|

Power(KW) |

15kw |

30kw |

|||

|

Hydraulic System |

System Pressure (Mpa) |

32 |

32 |

||

|

Flow(L/min) |

18 |

47 |

|||

|

Oil Tank capacity(L) |

280 |

280 |

|||

|

Type of Hydraulic Oil |

Operating Ambient Temperature35℃~50℃ |

L- HM68 |

L- HM68 |

||

|

Operating Ambient Temperature5℃~35℃ |

L- HM46 |

L- HM46 |

|||

|

Operating Ambient Temperature-15℃~5℃ |

L- HM32 |

L- HM32 |

|||

|

Control Mode |

Cable Remote control |

||||

|

Wireless Remote Control |

|||||

|

Wired Remote Control |

|||||

|

Cleaning Mode for Delivery Pipeline |

Water Wash/Dry Cleaning |

||||

|

Section of Tubular Column(m×m) |

0.75×0.75 |

||||

|

ARM |

Boom Mode |

Fully Hydraulic |

Fully Hydraulic |

||

|

Delivery Pipeline Diameter |

DN125 |

DN133 |

|||

|

Length of End Hose(″× m) |

5"×3 |

5"×3 |

|||

|

1st Section |

Length (m) |

14.9 |

8.86 |

||

|

Articulation |

-2.5°〜 82.5° |

0°〜 90° |

|||

|

2nd Section |

Length (m) |

9.6 |

7.96 |

||

|

Articulation |

0°〜180° |

0°〜180° |

|||

|

3nd Section |

Length (m) |

8.5 |

7.96 |

||

|

Articulation |

0°〜180° |

0°〜180° |

|||

|

4nd Section |

Length (m) |

NON |

7.96 |

||

|

Articulation |

-- |

0°〜180° |

|||

|

Climbing |

Climbing Type |

Cylinder Jack Lifting |

|||

|

Internal Climbing Step Distance(m) |

0.52 |

||||

|

Floor Frame |

Hole Prepared in Floor |

||||

|

Shaft Frame |

Size of Climbing2.0m - 2.7m |

||||

|

Boom |

|

■The arced boom structure is optimized by applying CPU design. The boom adopted high-strength steel plate for production with scientific process. It features beautiful appearance, superior rigidity and intensity, ensuring excellent and reliable quality. |

|

|

Hydraulic System |

|

■G series products adopted world-famous Germany Rexroth oil pump, proportional valve (with operating handle) and balance valve with secondary overflow, while C and E series products adopted Germany Rexroth solenoid directional control valve and balance valve with secondary overflow. It has effectively avoided the potentialdamages of boom which might be caused by overspeed movement when the boomdrops down, and sudden increase of oil cylinder’s pressure under external forces, thus the reliability of the boom has been increased. |

|

|

Inner Hydraulic Oil Tank |

|

■Inner hydraulic oil tank renders a compact structure and free swivel. It gives big convenient for installation, dismounting and maintenance, which ensure longer service life and excellent performance. |

|

|

Climbing Facility |

| ■As a rectangular frame structure, the climbing facility is flexible, reliable and convenient for dismounting. | |

|

Slewing Mechanism and Reducer |

|

■Slewing reduer adopted products made by the world-famous brand of Italy Comer, with a great torsion. Being accompanied with the integrated slewing balance valve made by Germany Hawe, it achieves smooth operation and reliable and stable performance. |

|

|

Wireless Remote Controller |

|

■G series products adopt industry-exclusive analogue wireless remote controller made by Germany Hetronic, along with the proportional valve made by Germany Rexroth,it makes movement smooth, hydraulic impact limited, and performance reliable. Apart from that, it makes possible the stepless speed regulation and multi boom and slewing interaction, which enhanced work efficiency greatly. ■C and E series products adopt industry-exclusive analogue wireless remote controller made by Taiwan TELECRANE, which is easy and convenient to operate, highly resistant to disturbance and reliable in performance. ■Each series are accompanied with wired remote controller for use in necessity. |

|

|

Electric Control System |

|

■The electric control system adopted world famous brand of electric components, such as Japanese Omron and French Schneider. The multi automatic protection is set up in the control program, so as to avoid misoperation and ensure the system's reliability. |

|

|

Column |

|

■The column is made of high-strength steel plate in square shape, with nice appearance, rigidness and intensity, as well as high reliability. |

Previous

Next

Get a quote